The Role of Process Optimization in Mitigating Labor Scarcity

One of the most pressing pain points for modern facilities is the widening skills gap.

Conocimiento de la industria por parte de expertos de la industria.

One of the most pressing pain points for modern facilities is the widening skills gap.

By creating a detailed visual and data-driven representation of how power, water, and compressed air move through a facility, engineers can identify exactly where resources are being lost.

A digital twin is more than just a 3D model; it's a virtual, living replica of a physical process, facility, or entire supply chain. It provides a risk-free environment for experimentation.

General uncertainty over changes in Mexican regulations can complicate long-term investment planning. High-precision documentation is key to maintaining regulatory compliance in Mexico for facility operations.

For manufacturing in Mexico to achieve true, long-term resilience, it must evolve beyond an assembly hub. The strategic imperative is to accelerate the development of a robust local component base and become more vertically integrated.

Implementing a full-scale Industry 4.0 transformation can seem daunting, but it's a journey that can be broken down into manageable steps.

Manufacturing an electric vehicle presents a unique set of challenges that distinguish it from traditional internal combustion engine assembly. The entire process, from component handling to final testing, introduces new complexities that demand a more intelligent approach to facility design.

Within the broader landscape of nearshoring, certain locations have emerged as centers of excellence. The city of Saltillo stands out as a premier destination for industrial and automotive manufacturing, offering a unique combination of resources and strategic positioning.

Manufacturing execution systems (MES) provide the real-time visibility and control necessary to combat downtime directly, transforming plant floor operations from reactive to proactive.

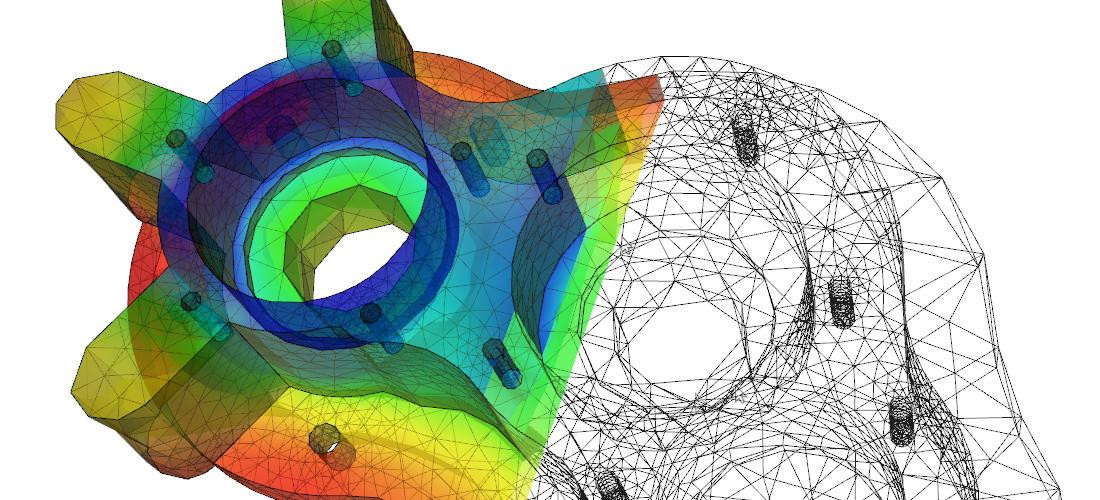

Think of finite element analysis as a virtual testing ground for real-world conditions. The process works by taking a complex 3D design and digitally breaking it down into thousands of smaller, simpler pieces, or elements.

Querétaro, Mexico, boasts a strategic location that positions it as a cornerstone of the nation's industrial development. Its geographic advantages, including proximity to major transportation routes and access to a skilled labor pool, make it highly attractive for businesses.

This article will explore how finite element analysis plays a pivotal role in ensuring the safety and robust design of aerospace components, a contribution particularly relevant for aerospace manufacturing in Mexico.

For manufacturing in Mexico, embracing Industry 4.0 is not just an option, but a necessity for sustained competitiveness and growth. At the heart of this transformation lies the manufacturing execution system (MES), a vital tool enabling the transition to smarter, more efficient production.

A powerful solution emerging to meet the challenges of a rapidly changing manufacturing industry, and unlock optimal production is the implementation of Manufacturing Execution Systems. This article explores how adopting MES can significantly enhance efficiency within Mexican automotive OEM assembly plants.

Explore how DSM’s G-Comply framework and on-site safety supervisors empower manufacturing companies to navigate the complexities of Mexican safety standards, minimizing risks and fostering secure work environments.