Why Your 2D/3D Asset Precision is the Key to Fast-Tracking Customs and Compliance

October 27, 2025The modern global manufacturing landscape demands speed and accuracy, but few manufacturers realize how deeply their engineering documentation—specifically their 2D and 3D assets—impacts their bottom line at the border.

The ability to seamlessly move goods and equipment across international lines, especially into and out of Mexico, relies heavily on the precision of digital data detailing equipment specifications, origins, and installation placements.

For operations exporting to the US market, this precision isn't just a technical detail; it's the difference between smooth logistics and costly detention.

Assets, Specifications, and Customs Declarations

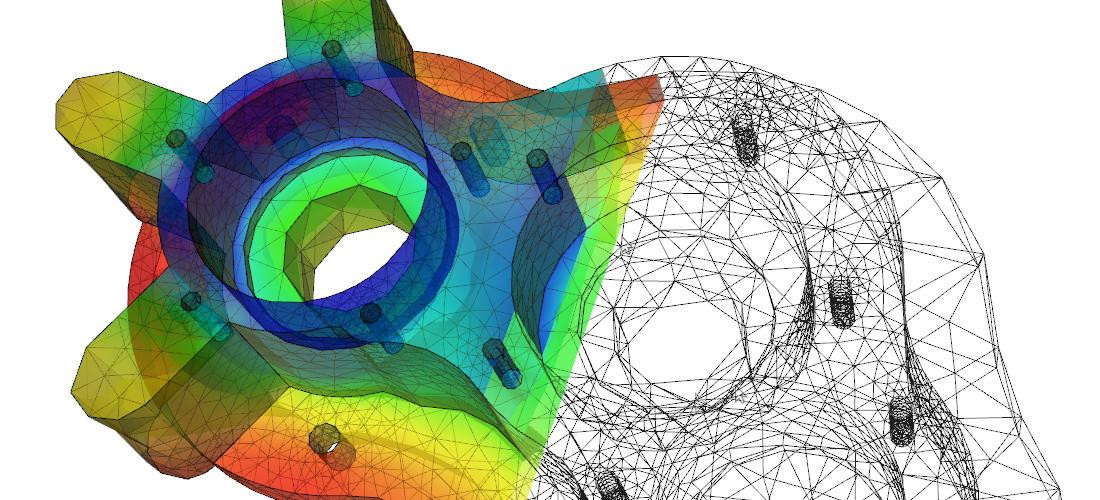

Modern import/export regulations for industrial equipment require comprehensive documentation that verifies the contents of a shipment. Precise 3D assets and supporting 2D drawings are the core of this verification process.

Our expertise at Design Systems de Mexico (DSM) focuses on ensuring that documentation created in standard software, such as AutoCAD and Inventor, contains all the crucial data points:

Accurate Equipment Specifications: Exact dimensions, materials, and technical features necessary for proper identification.

Origin and Placement: Clear, traceable records of a component's country of origin and its final installation location within a facility.

This verifiable digital record is essential for simplified tariff categorization and smooth cross-border customs inspections, preventing confusion and delays that often plague undocumented shipments.

Addressing Trade Uncertainty

Today's geopolitical environment introduces significant risks to manufacturing supply chains. High-precision engineering documentation is the strategic tool used to mitigate the three primary pain points faced by exporters:

Mitigating Tariff Risk and Classification Errors

The potential for new tariffs or major shifts in US trade policy creates significant instability. This political uncertainty translates directly into tariff risk for any heavy exporter.

Accurate 3D assets are critical because they ensure the correct Harmonized System (HS) code classification is applied before the shipment leaves your facility. Misclassification is the single most common trigger for unexpected duties, financial penalties, or costly delays at the border. Solid, verifiable documentation limits the discretionary power of customs officials, significantly lowering the risk of a shipment being improperly detained or subjected to incorrect tariffs.

Meeting USMCA Rules of Origin Requirements

For manufacturers operating under the United States-Mexico-Canada Agreement (USMCA), strict Rules of Origin requirements demand complex adjustments to sourcing strategies.

Documentation created using tools like AutoCAD or Inventor must clearly trace the origin of every major component. These detailed 3D assets act as the verifiable evidence that a product meets the necessary Regional Value Content (RVC) thresholds. This level of precision is vital for securing preferential tariff benefits and is absolutely necessary to prevent a product from being caught in a compliance audit, securing your ability to operate successfully in North American manufacturing.

Navigating Regulatory Compliance in Mexico

General uncertainty over changes in Mexican regulations can complicate long-term investment planning. High-precision documentation is key to maintaining regulatory compliance in Mexico for facility operations.

For instance, high-precision 2D and 3D assets for installation placement and equipment detail are necessary for internal and external audits to demonstrate adherence to local safety and construction standards.

Our specialized service, Safety Supervisors utilizing G-Comply, relies on this level of accuracy. By having proactive documentation, you ensure smooth approval processes and demonstrate adherence to the stringent safety and operational requirements mandated locally, protecting your investment and minimizing operational risk.

The Strategic Value of Engineering Documentation

Engineering precision, enabled by specialized tools like AutoCAD and Inventor, is far more than a technical requirement; it’s a critical function that influences trade, financial exposure, and regulatory compliance in Mexico. Utilizing detailed 3D assets future-proofs your operations, helping you unlock a more efficient, predictable, and streamlined future for high-value manufacturing in North America.

Unlock the key to a more efficient and streamlined future. Learn how our comprehensive engineering and consulting solutions can enhance your operations from start to finish.

Contact Design Systems de Mexico today to ensure your engineering assets accelerate—rather than impede—your compliance and cross-border trade.